With the continuous advancement of the construction of smart city, the traditional communication system is faced with the three challenges of big data, large traffic and large energy consumption. In the era of 5G, the form, power consumption, site and coverage of the distributed base stations of mobile communication are constantly being upgraded, requiring higher bandwidth, lower latency and more connections. To adapt to these features, more reliable and economical power supply solutions are needed for new base stations. Intelligent communication energy system can support data information exchange and sharing in any scenario (indoor, outdoor), providing power energy solutions for base stations and communication equipment.

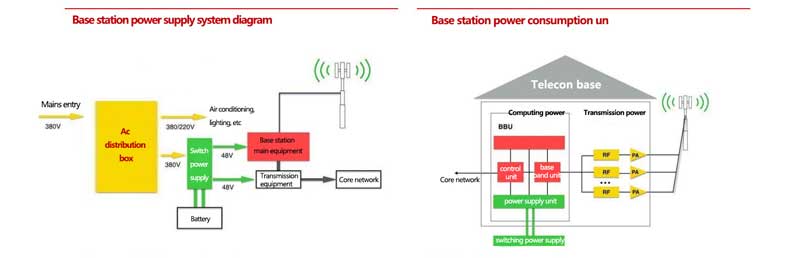

Communication iron tower system is an important part of communication infrastructure, including iron tower, machine room (cabinet), supporting facilities and station site. Iron tower is the core asset of communication tower system, which is used to carry communication antenna and is an important carrier of communication network. The machine room includes self-built and leased two modes, used to carry carrier communication equipment. The supporting equipment of the tower system includes mains, distribution box, switching power supply, battery, air conditioning, FSU, etc., which provide the necessary support for the normal operation of the tower system.

In the 4G era, the maximum power consumption of a single base station can reach 1300W. Since 5G uses a larger array antenna and higher bandwidth, the base station will process massive data, and the energy consumption is significantly higher than the original 3G and 4G base stations. In this application scenario of base station battery expansion, lead-acid batteries are gradually replaced by lithium iron phosphate batteries in terms of use cost and performance. This shift has led to the development of advanced telecom battery backup systems.

The voltage of this series of batteries is 48V, and it is suitable for the backup power supply of various communication equipment, such as base stations, switches, routers, etc. Designed by ece energy, its high energy density can meet the needs of the long-time operation of the equipment, and the long-life design can effectively reduce the frequency of battery replacement and save the maintenance cost. The quick charging function can greatly shorten the charging time and improve the operating efficiency of the device.

In addition, this series of batteries also has excellent high temperature resistance and vibration performance, can maintain stable performance in extreme environments. The battery interior adopts advanced protection circuit design, which can effectively prevent overcharge, overdischarge, short circuit and other safety problems, and ensure the safety and reliability of equipment operation. The 48V lithium iron phosphate communication backup battery series provides more efficient, more reliable and safer solutions for the backup power supply, and makes the operation of communication equipment more stable and reliable. These features make it an ideal choice for telecom battery backup systems.

High Speed and Efficiency: 5G UPS (Uninterruptible Power Supply) station batteries support the high-speed data transmission rates of 5G networks. This ensures that the network operates efficiently, even in the event of a power outage.

Reliable Power Supply: These batteries provide a reliable power backup solution for 5G stations, ensuring uninterrupted network service. This is crucial for maintaining connectivity and preventing data loss.

Long Lifespan: 5G UPS station batteries are typically designed for long-term use, reducing the need for frequent replacements and thus lowering maintenance costs.

Methods to improve the efficiency and stability of lithium battery management mainly include real-time monitoring and diagnosis, implementation of precise charge/discharge control, thermal management optimization, temperature management, application of balancing technology, software and hardware synergy, regular maintenance and user education and training.

(1) Real-time monitoring and diagnosis: Use advanced sensor technology to monitor the temperature, voltage, current and other key parameters of the battery in real time. Combined with big data analysis and machine learning algorithms, the collected data is analyzed in depth to identify potential signs of failure or performance degradation. Intelligent algorithms are used to predict battery life and take measures in advance to avoid sudden failures.

(2) Precise charge/discharge control: Dynamically adjust the charging strategy according to the actual state of the battery (e.g., state of charge SOC) to avoid overcharging or undercharging. When the battery is close to full or empty, a more moderate charging and discharging rate is used to reduce damage to the battery.

(3) Thermal management optimization: Design efficient heat dissipation systems, such as liquid cooling or air cooling systems, to ensure that the battery works at the optimal temperature. Use thermal simulation models to predict the thermal behavior of the battery under different working conditions and optimize the heat dissipation layout and fan speed.

(4) Temperature management: Keep the battery working within the appropriate temperature range. Excessively high or low temperatures will affect battery performance and life. Battery temperature can be controlled through heat dissipation design, temperature sensor monitoring and thermal management system.

(5) Application of equalization technology: For battery packs used in series or parallel, adopt active or passive equalization technology to ensure the consistency of the charge state of each battery cell. Regularly check the consistency of the battery pack, and timely replace the mismatched battery cells.

(6) Collaboration between software and hardware: Develop a highly integrated battery management system (BMS) to realize the seamless connection between software and hardware. Utilize advanced communication protocols, such as CAN bus or wireless communication, to realize remote transmission and monitoring of battery data.

(7) Regular maintenance: Conduct regular inspections and maintenance of the battery, including cleaning, tightening connections, and checking insulation. Timely detection and treatment of potential problems to extend battery life.

(8) User education and training: Provide users with best practice guidelines for battery use and maintenance. Regular user training events are held to teach how to properly operate and maintain battery equipment.

Through the above methods, we can effectively improve the efficiency and stability of battery management, extend battery life, reduce maintenance costs, and at the same time enhance the safety of the equipment and user experience.

Install photovoltaic energy storage systems for your own home or company to save money and stabilize electricity consumption

Find a stable and reliable factory to assist you in expanding the market locally

Professional technical team and reliable energy storage products to provide a guarantee for your engineering project